Understanding POD Printing Technologies

In the world of print-on-demand (POD) and custom apparel printing, choosing the right printing technology can significantly impact your business success. Each method comes with its own strengths, production time, minimum order quantity, and ideal use cases. Whether you’re starting a new POD dropshipping brand or expanding your existing product line, having a solid understanding of different printing methods for POD is essential.

Why Knowing Printing Methods Matters

This article is the first part of a two-part series that explores the most popular POD printing technologies available today. By learning how each method works, you can make informed decisions, reduce production risks, and increase your chances of creating high-quality, sellable products.

Different printing technologies also vary in production lead times, setup requirements, and order minimums, so if you’re curious about pricing or need personalized advice, don’t hesitate to contact us for a quote or consultation.

Now, let’s dive into the various POD printing methods and explore how they can fit your brand, whether you’re focused on custom T-shirts, apparel, or other merchandise.

What Is Direct-to-Garment (DTG) Printing?

Direct-to-Garment (DTG) printing is a digital printing method that transfers computer-generated designs directly onto fabrics or other materials. Using advanced RIP software and specialized print heads, water-based or reactive dyes are sprayed directly onto textiles. After a finishing process, the result is a high-resolution, durable print that is widely used in both the fashion and textile industries.

The DTG Printing Process

- Design Creation

Designers use computer software or drawing tools to create artwork. The design can be tailored to fabric type and color requirements. - Fabric Preparation

Fabrics such as cotton, polyester, or blends are selected. The material must be dry, flat, and wrinkle-free. Some textiles may require pre-treatment like heat-setting or starch removal. - Color Preparation

Depending on the design, commonly water-based, reactive, or acid dyes will be chosen for their lightfastness and wash resistance. - Printer Setup

The digital inkjet printer is calibrated according to fabric type and design requirements. Parameters like ink flow, nozzle spacing, and resolution are adjusted for the best results.Printing the Design

The digital artwork is transferred to the DTG printer, and the fabric is positioned on the print bed. The design is then directly applied onto the fabric surface. - Drying and Curing

Once printed, the fabric undergoes drying and curing (typically with heat press or dryers) to ensure the ink bonds firmly with the fibers. - Post-Treatment

After curing, finishing steps such as washing, ironing, and cutting are applied to enhance durability and appearance.

Advantages of DTG Printing for Custom Apparel

Cost-Effective for Small Orders

DTG eliminates the need for screen plates or complex setup. Even single pieces, like T-shirts or custom merch, can be produced affordably with shorter lead times.

Soft and Comfortable Finish

DTG inks penetrate fabric fibers at the nano level, leaving the fabric soft and breathable while maintaining durability.

Ideal for Complex Designs

DTG excels at reproducing intricate patterns, gradients, and photo-realistic images. The technology captures fine details and vibrant colors with ease, making it perfect for personalized apparel.

Eco-Friendly & Sustainable

DTG printing uses water-based inks and does not require chemical treatments or extensive water washing, reducing environmental impact and conserving resources. This makes it a sustainable choice for brands that prioritize eco-conscious practices.

Tip: If your brand emphasizes sustainability or eco-friendly values, DTG printing is an excellent choice to align your products with your brand identity.

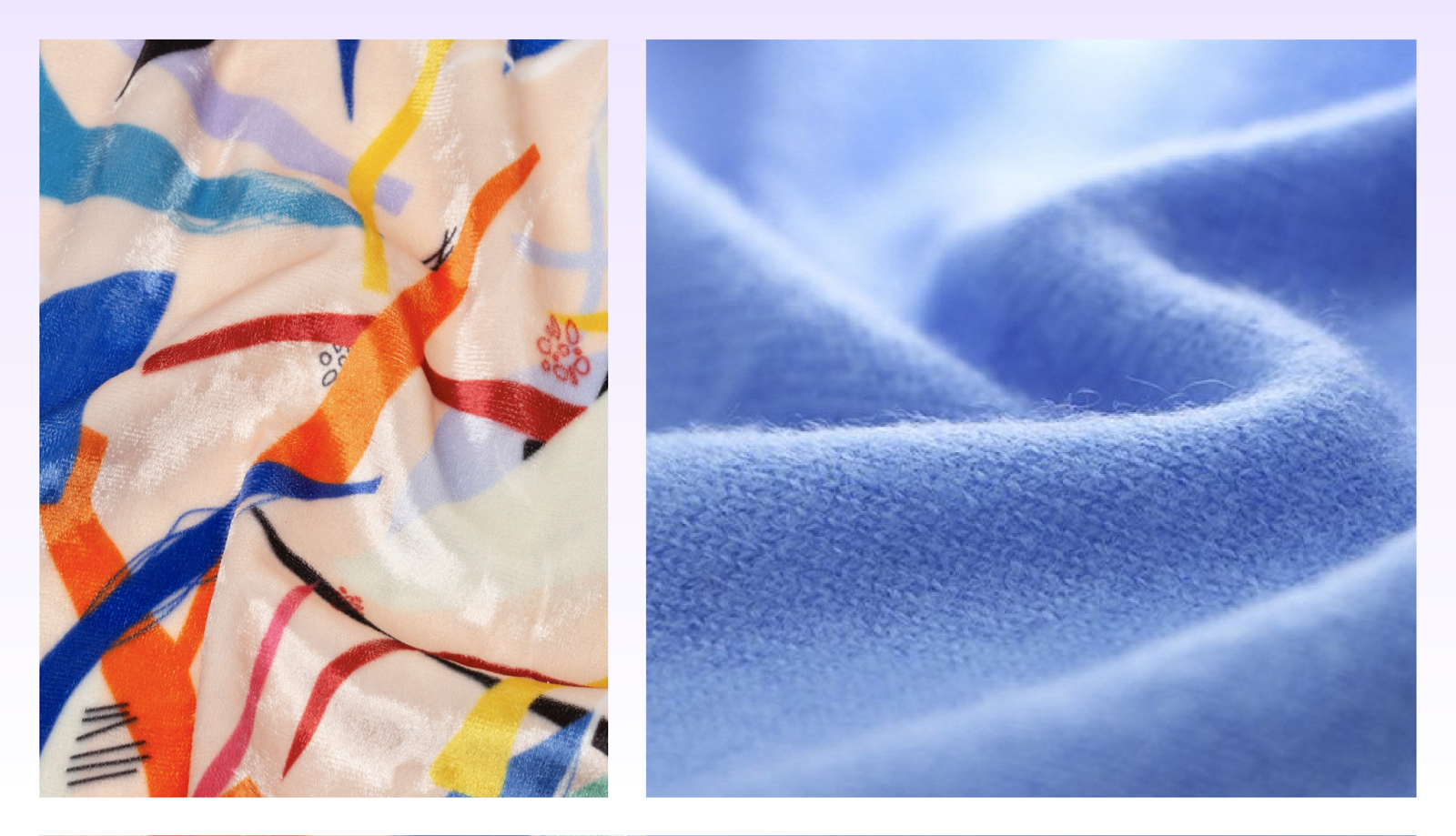

What Is Sublimation Printing?

Unlike standard heat transfer printing, sublimation relies on a special process where dye molecules change directly from solid to gas under high heat and pressure, bonding permanently with the substrate. At temperatures around 400–450°F, the printed image on transfer paper turns into gas and penetrates the fibers or coating of the material. Once cooled, the design becomes part of the product itself which is vivid, durable, and resistant to fading.

This is why sublimation prints don’t simply sit on the surface of the fabric or object. Instead, they integrate seamlessly, achieving photo-quality results with bright, long-lasting colors.

Applications of Sublimation Printing

Sublimation is extremely versatile and is commonly used for:

- Apparel & Accessories: Sportswear, T-shirts, scarves, headbands, bandanas

- Home Décor: Cushion covers, pillowcases, tablecloths, curtains

- Hard-Surface Products: Coated wood, glass, ceramic mugs, metal panels

- Everyday Items: Pens, clocks, tumblers, and other promotional merchandise

For POD sellers and dropshipping businesses, sublimation offers the opportunity to expand product catalogs with highly customizable and profitable items.

Advantages of Sublimation Printing

- Unlimited Design Possibilities

From complex artwork to photo-realistic images, sublimation supports full-color, detailed designs with no limitations. - Vibrant Colors and Fine Detail

Sublimation dyes deliver brilliant hues, sharp details, and smooth gradients, making products stand out in a competitive POD market. - Exceptional Durability

Prints are embedded into the material, ensuring they won’t fade, crack, or peel, even after repeated washing. - Cost-Effective for Small Orders

With no setup fees or screens required, sublimation is ideal for small-batch ordersor one-off custom products which is perfect for dropshippers testing new niches. - Eco-Friendly Process

Compared to traditional printing methods, sublimation uses minimal water and reduces ink waste aligning well with sustainable brand positioning. - Future Growth Potential

As technology advances, sublimation printing continues to evolve, opening new possibilities for custom POD products.

Conclusion

Choosing Max Dropshipping means not just finding a POD supplier, it’s also partnering with a team committed to speed, quality, and flexibility. With faster turnaround times, access to a vast network of over 2,000 trusted factories, strict quality assurance, and advanced in-house printing technology, Max empowers brands to scale efficiently by delivering consistent, high-quality products to their customers.

There’s more to POD printing than we can cover in this article! Click hereto explore techniques like screen printing, heat transfer, and embroidery designed to help you take your brand and business to the next level.